108475, RE: Water injection questions

Posted by ez, Dec-31-69 06:00 PM

Originally posted by CODE4

With said pump, is there a controller as well?

No need for one. Turn it on with boost, turn it off when off boost. While there is a school of thought that thinks increasing water volume with fuel volume is optimum (via PWM like the MS, a FPR type of setup, or other type of controller), I suscribe to the K.I.S.S. route. These guys seem to agree: http://www.rbracing-rsr.com/waterinjection.html To put it in their words "You have to eliminate the variables, not increase them."

You can use a boost switch or MS to do the on/off switching. I will use emanage.

Is there a voltage regulator to feed the pump or will the output vary with system voltages?

The pump requires 220V AC. There is another pump available that requires 110V AC, however it runs hotter. Therefore you need a 12V to 220V inverter. Again, do not vary voltage, for the reasons rbracing mentions.

Does the system require a pressure regulator of any kind?

I prefer to avoid this route.

What calculations are you using/will you use to establish flow volume & pressure?

Regarding pressure:

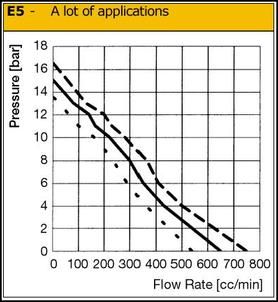

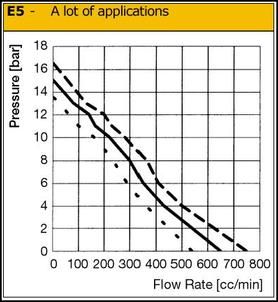

To keep things simple, I am looking at pumps that are capable of 15bar, so the 1 to 1.5 atm of boost pressure will not affect flow too much.

Regarding volume:

It appears that in spite of all the sophisticated electronics and controllers that water injection kit companies utilize, it really ends up coming down to the little nozzle you stick at the end of a hose. So, I believe it's easiest to simply get a high pressure pump capable of the volumes you need, and then pick a nozzle that will give you 10-15% volume of fuel you are injecting. The highest flow that professionals use appears to be approximately 25% of fuel requirements.

Thinking out loud here...I will aim for ~10% (water volume/fuel volume) I need at 20psi at redline. Which means that below this peak fuel requirement, I will be putting much more water than needed at lower RPMS. That's ok, no harm will occur. If the engine bogs, I will reduce my nozzle size.

The question is, how much do fuel do I need at 20psi in cc/min? Am I aiming for 12.5 AFRs with water injection? Suppose I need 1200 cc/min of fuel at this level of boost, then I need 120 - 180 cc/min of water.

I just don't know where to start with nozzle sizing, because they give you a GPM number on each nozzle, but don't tell you what the GPMs are at each pressure. I would almost have to experiment here with each nozzle on my pump.

I am interested in H2O injection as well in FL for the same reasons. A DIY kit is well worth the R&D.

Then let's make progress on this in 2011!

|