| Go back to previous topic | |

| Forum name | Performance/Engine |

| Topic subject | 2.4L main stud information |

| Topic URL | http://forums.2gnt.com/dcboard.php?az=show_topic&forum=5&topic_id=125845 |

|

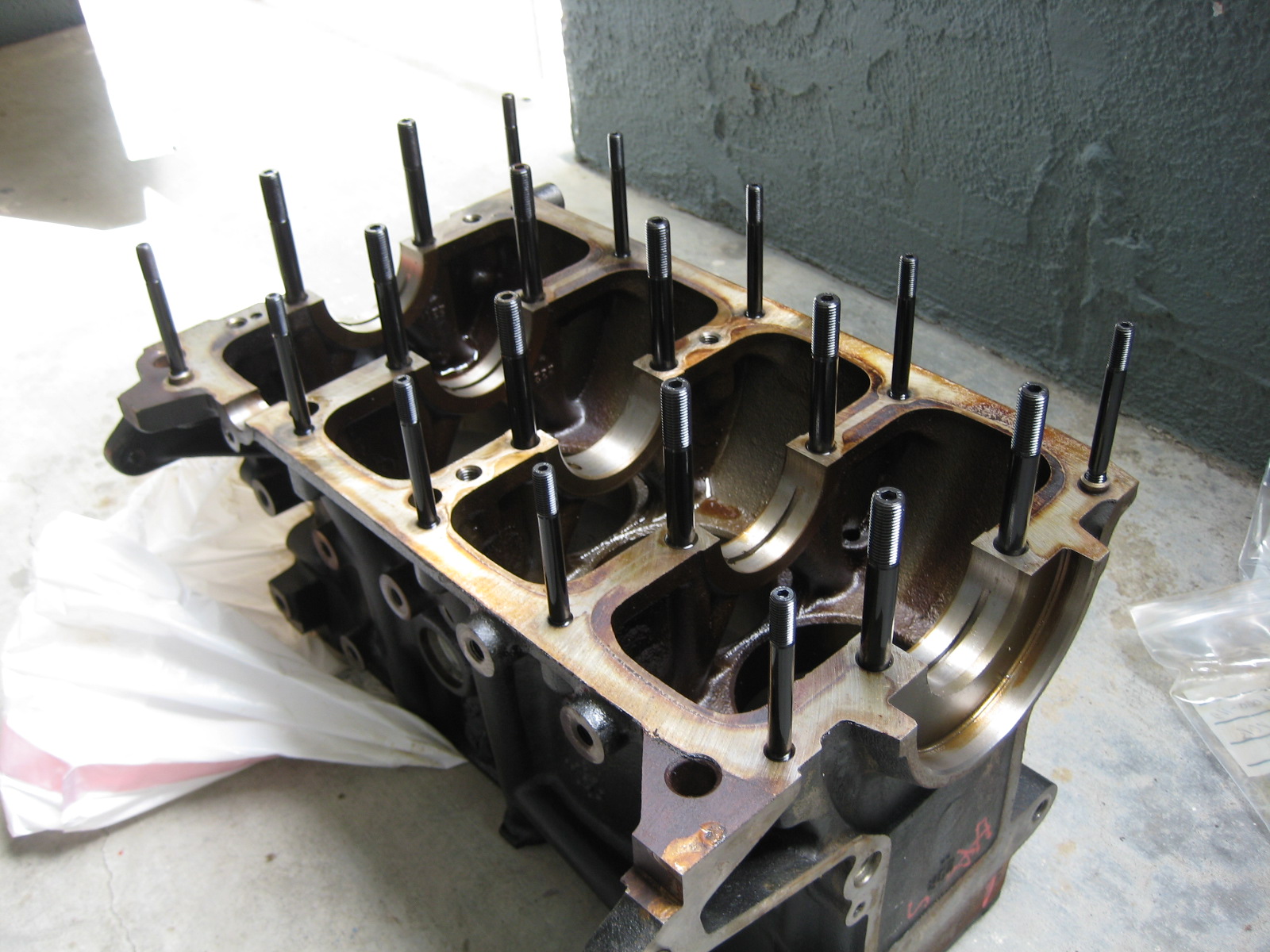

125845, 2.4L main stud information Posted by CODE4, Dec-31-69 06:00 PM Realizing that ARP does not make a main stud kit for the 2.4L block (weird) I got crack-a-lackin on filling out there stud application chart. Spoke with Modern Performance and they said they always re-use the OEM main bolts. A few posts over @neons.org mention that guys run the ARP kit 141-5801 for the 2.0 however there is not 100% thread engagement by the nut. Their solution? Back the stud out a thread or two from the block. :rolleyes | |

|

125846, RE: 2.4L main stud information Posted by 420agreenvilleSC, Dec-31-69 06:00 PM Excellent information. Definately WIKI worthy. You're an asset to this community. No doubt, props for you my friend. :thumbsup | |

|

125847, RE: 2.4L main stud information Posted by DarkOne, Dec-31-69 06:00 PM $200? | |

|

125848, RE: 2.4L main stud information Posted by CODE4, Dec-31-69 06:00 PM I know, I know Dino :p | |

|

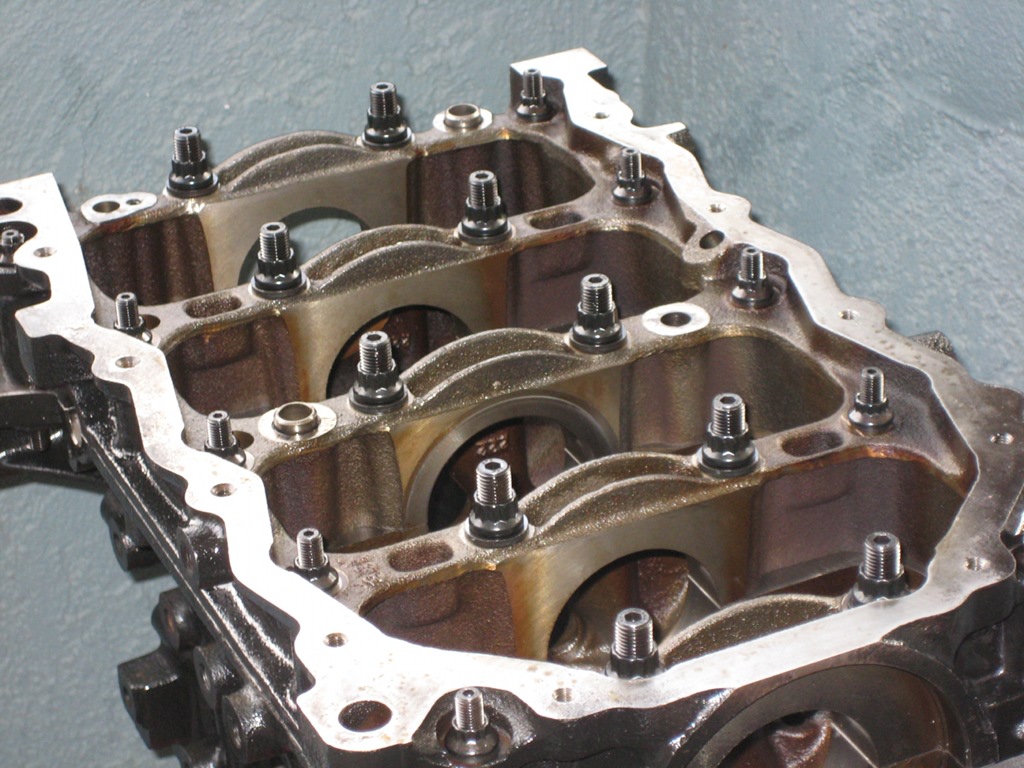

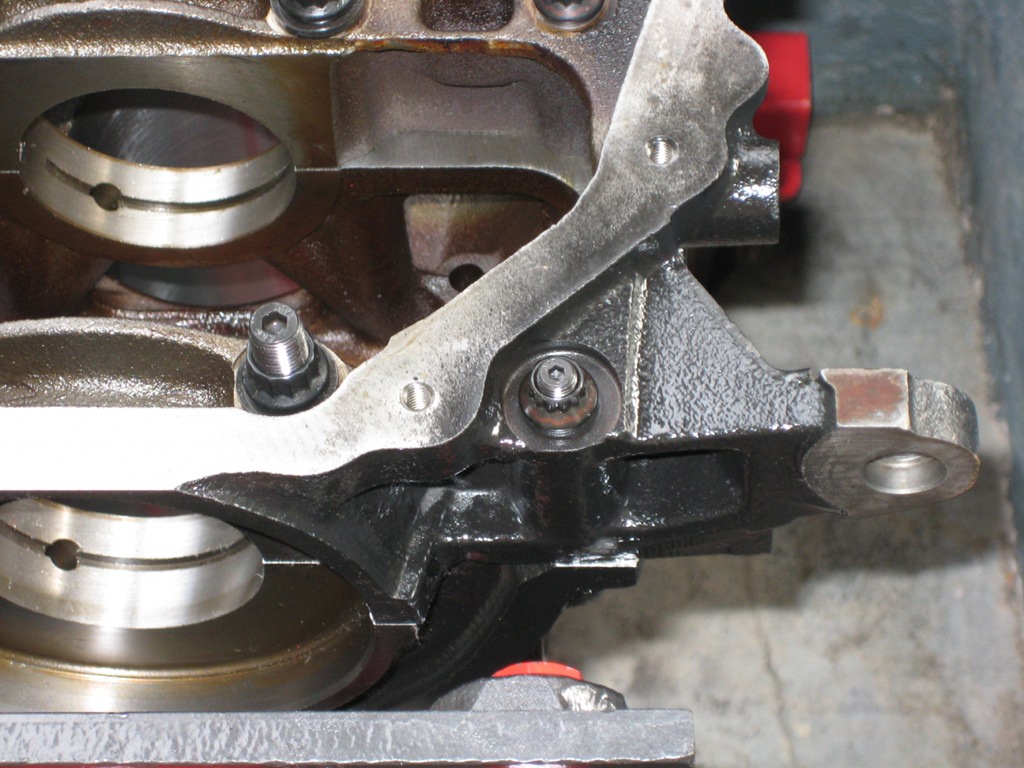

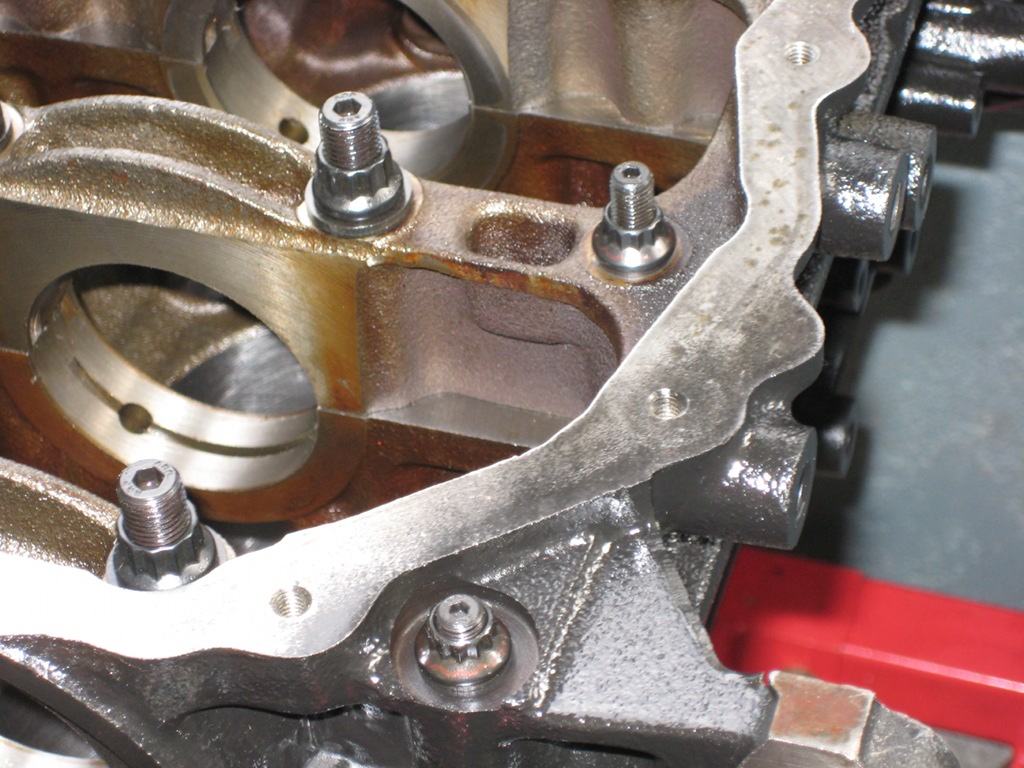

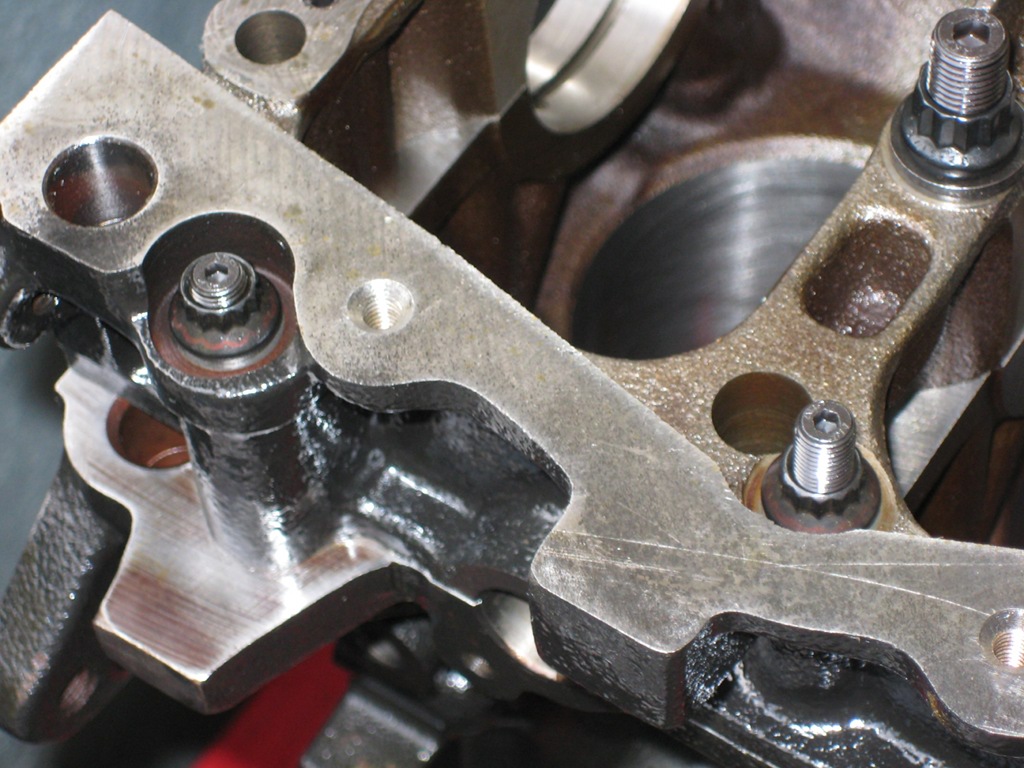

125898, RE: 2.4L main stud information Posted by CODE4, Dec-31-69 06:00 PM Received the ARP studs/washers/nuts today. The M11 combination works well. A slight problem with the M8 studs however - with the washer used there is maybe 0.5mm spacing left where the nut is running out of thread - meaning the nut will not torque down properly. After speaking with Paul over at ARP again he mentioned that he has a M8 washer that is double thick but to first use a bottoming tap in the holes. There is at least a couple millimeters in the bottom of the blind hole in the block that can be used to gain a few extra threads, which in combination with the thicker washer may solve the problem. | |

|

125899, RE: 2.4L main stud information Posted by 420agreenvilleSC, Dec-31-69 06:00 PM

| |

|

125900, RE: 2.4L main stud information Posted by 1slw97, Dec-31-69 06:00 PM Thanks for the info, I been rounding stuff up for a 2.4 build this winter. | |

|

125919, RE: 2.4L main stud information Posted by PsychO, Dec-31-69 06:00 PM Man, if this was around earlier I would have jumped on it, it's great info. I went with all new OEM studs for the main and bedplate on my 2.4. I hope I don't see any issues down the road, though. | |

|

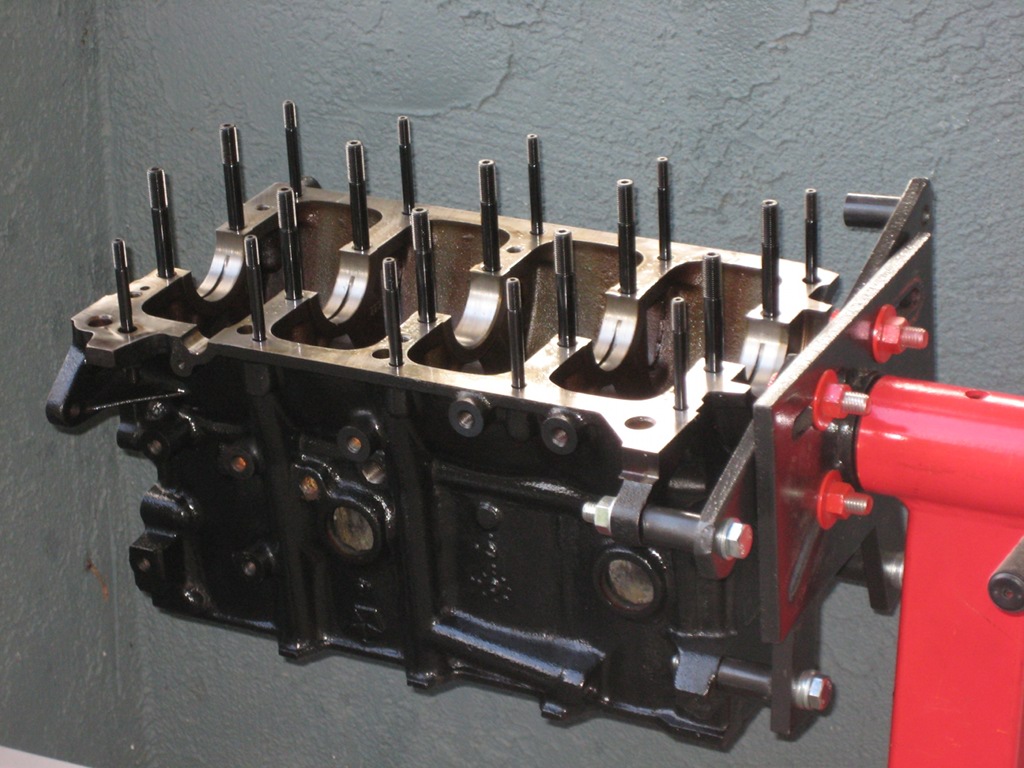

126890, RE: 2.4L main stud information Posted by CODE4, Dec-31-69 06:00 PM Since this main stud kit was pieced together from completing the stud application form from ARP it is not a plug and play. The M8 studs available are either too short or a tad too long. Run as is, the M8 nuts will run out of thread before you can accurately have a torque reading. Solution? | |

|

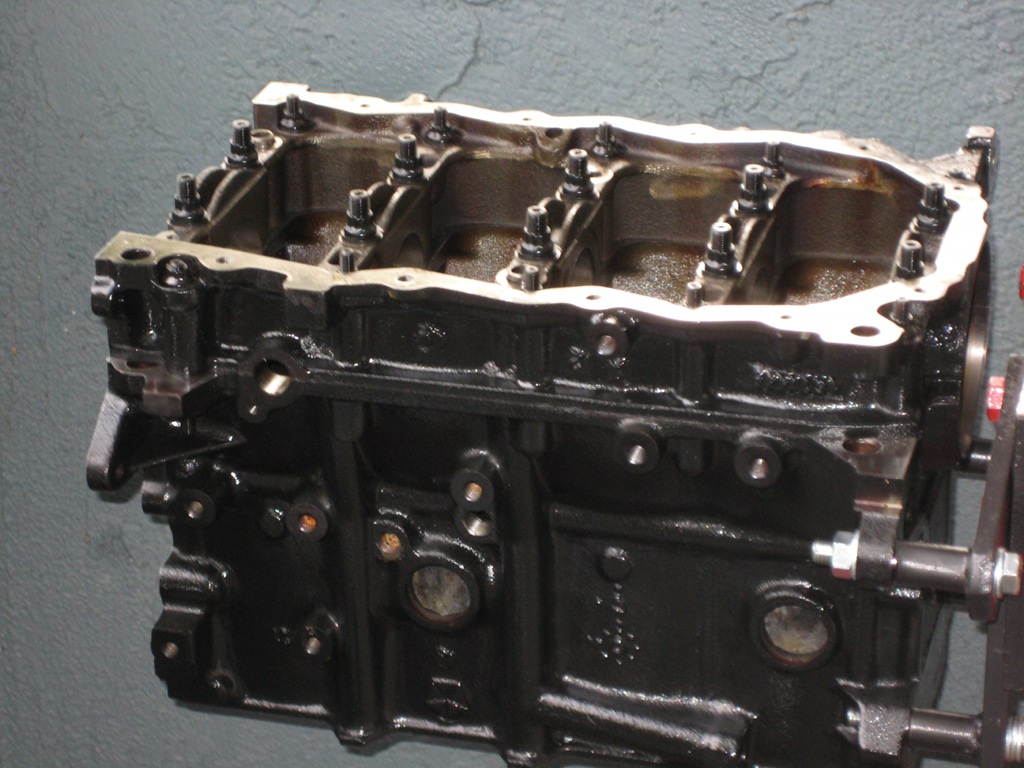

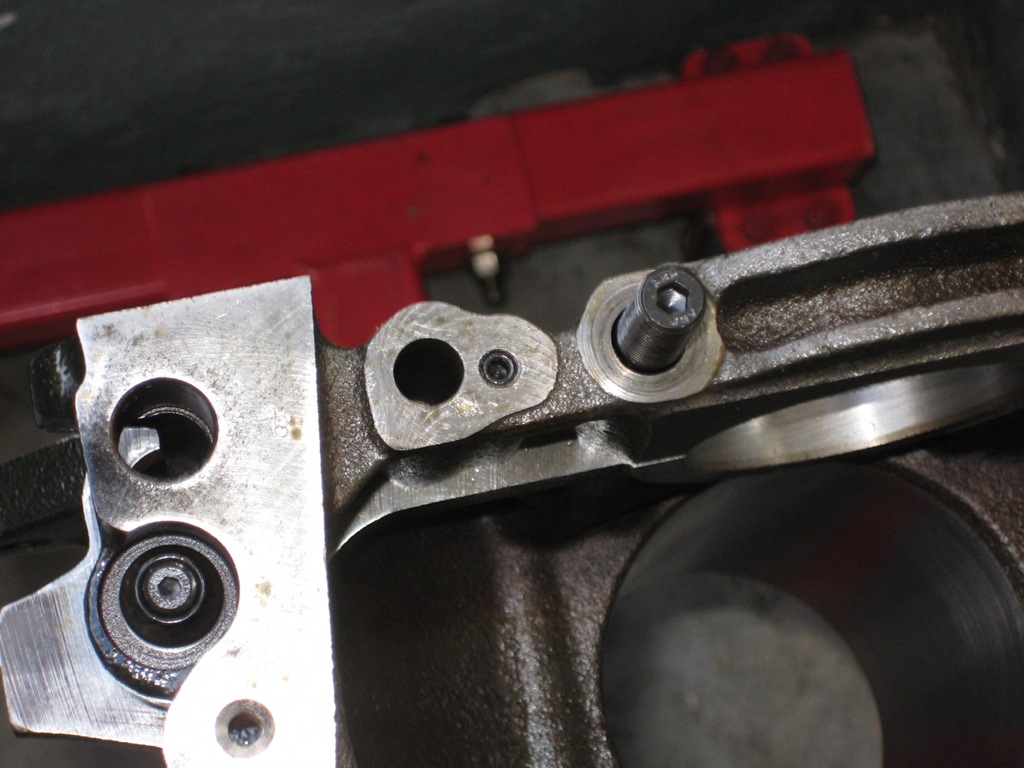

126891, RE: 2.4L main stud information Posted by CODE4, Dec-31-69 06:00 PM And the SRT pan for looks: | |

|

126993, RE: 2.4L main stud information Posted by CODE4, Dec-31-69 06:00 PM Brass expansion plugs are in. | |

|

126996, RE: 2.4L main stud information Posted by 420agreenvilleSC, Dec-31-69 06:00 PM god. this makes my 2.0 build look like fuckn CRAP | |

|

127001, RE: 2.4L main stud information Posted by CODE4, Dec-31-69 06:00 PM Hahah... I take that as a compliment I guess. | |

|

127004, RE: 2.4L main stud information Posted by CODE4, Dec-31-69 06:00 PM This Information has been Wiki'ed. | |